Flange Size Chart PDF⁚ A Comprehensive Guide

A flange size chart PDF is an invaluable resource for engineers, designers, and anyone involved in piping systems. These charts provide detailed dimensions, specifications, and other essential information for various flange types and sizes. They are particularly useful for ensuring proper connections and maximizing the efficiency and safety of piping systems.

Introduction

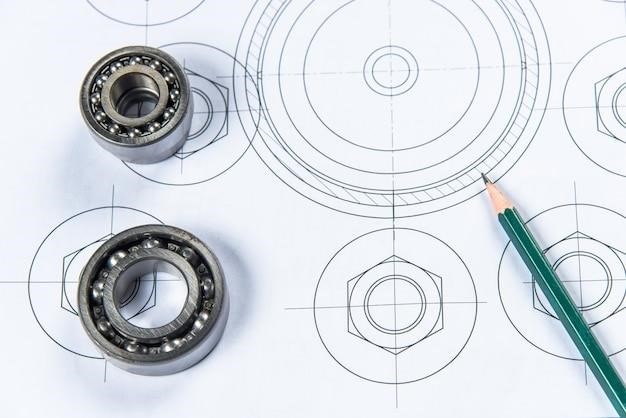

Flanges are essential components in piping systems, serving as connection points for various pipes, valves, and equipment. Selecting the right flange size is crucial for ensuring a secure and leak-proof connection, as well as for maintaining the integrity of the entire system. A flange size chart PDF provides a comprehensive guide to the dimensions and specifications of various flanges, making it easier to choose the appropriate flange for a specific application.

These charts are often organized by flange type, pressure class, and nominal pipe size (NPS). They typically include information such as the outside diameter, bolt circle diameter, bolt hole diameter, flange thickness, and number of bolts. This information is essential for designing, installing, and maintaining piping systems, ensuring compatibility and optimal performance.

Flange size charts are available from various sources, including manufacturers, industry standards organizations, and online resources. They are particularly useful for engineers, designers, and technicians involved in piping projects, as they provide a quick and easy reference for selecting the correct flange size and ensuring compliance with relevant standards;

Understanding Flange Dimensions

Flange dimensions are critical for ensuring proper fit and function in piping systems. A flange size chart PDF provides a detailed breakdown of these dimensions, allowing for accurate selection and installation. Key dimensions to consider include⁚

- Outside Diameter (OD)⁚ The overall diameter of the flange, which determines its size and compatibility with other components.

- Bolt Circle Diameter (BCD)⁚ The diameter of the circle on which the bolt holes are located, ensuring proper alignment and spacing for bolting.

- Bolt Hole Diameter (BHD)⁚ The diameter of each individual bolt hole, ensuring a snug fit for the bolts used to secure the flange.

- Flange Thickness (FT)⁚ The thickness of the flange, which varies depending on the pressure class and material, providing strength and structural integrity.

- Raised Face Height (RFH)⁚ The height of the raised face, a critical dimension for sealing and ensuring a proper connection between flanges.

Understanding these dimensions is crucial for selecting the correct flange for a given application, ensuring compatibility with other components and achieving a secure and leak-proof connection;

ANSI B16.5 Standard

The ANSI B16.5 standard is a widely recognized and widely used standard for specifying the dimensions, tolerances, and other requirements for steel flanges used in piping systems. This standard provides a comprehensive set of guidelines for various flange types, pressure classes, and sizes, ensuring compatibility and interchangeability between flanges from different manufacturers.

The ANSI B16.5 standard covers flanges ranging in size from 1/2 inch to 24 inches and includes pressure classes ranging from 150 to 2500. It specifies dimensions for various flange types, including weld neck, slip-on, socket weld, threaded, lap joint, and blind flanges. The standard also includes information on bolt hole locations, raised face heights, and other critical dimensions.

By adhering to the ANSI B16.5 standard, engineers and designers can ensure that flanges meet the required specifications for strength, durability, and leak-proof connections, contributing to the overall safety and reliability of piping systems.

Flange Types

Flange size charts often categorize flanges based on their type, each designed for specific applications and connection methods. Some common flange types include⁚

- Weld Neck Flanges⁚ These flanges are designed for high-pressure applications and feature a welded neck that provides a smooth transition between the pipe and the flange, minimizing stress concentrations.

- Slip-On Flanges⁚ These flanges are slipped over the end of the pipe and welded to it. They are commonly used in lower-pressure applications and offer a cost-effective solution.

- Socket Weld Flanges⁚ These flanges are designed for smaller pipe sizes and feature a socket that allows for welding to the pipe. They offer a secure and compact connection.

- Threaded Flanges⁚ These flanges are connected to the pipe using threads. They are typically used for lower-pressure applications and offer a simple and convenient connection method.

- Lap Joint Flanges⁚ These flanges consist of a lap joint flange and a stub end. The stub end is welded to the pipe, and the lap joint flange is bolted to it. This design allows for easier removal and replacement of the flange.

- Blind Flanges⁚ These flanges are solid discs used to close off the end of a pipe. They are typically used for isolating sections of a piping system or for testing purposes.

Understanding the different flange types is essential for selecting the appropriate flange for a given application, ensuring a secure and reliable connection.

Flange Size Chart PDF⁚ Download Options

Finding a comprehensive and reliable flange size chart PDF is easier than ever thanks to numerous online resources and industry-specific websites. Here are some common ways to access downloadable flange size charts⁚

- Manufacturer Websites⁚ Many flange manufacturers offer downloadable PDF charts that showcase their product line, including dimensions, specifications, and material options. These charts are often tailored to their specific product offerings.

- Industry Associations⁚ Organizations like the American Society of Mechanical Engineers (ASME) provide standardized flange dimensions and specifications in downloadable PDF formats. These charts are often used as industry references for design and engineering purposes.

- Online Engineering Resources⁚ Several online platforms dedicated to engineering and design resources offer free or subscription-based access to downloadable flange size charts. These charts can be categorized by standard, pressure class, and other relevant parameters.

- Specialized Engineering Software⁚ Some engineering software packages include built-in flange size chart libraries or offer the ability to import external charts. This provides a convenient and integrated solution for designers working within these software environments.

When choosing a downloadable flange size chart, ensure it aligns with the relevant standards, materials, and pressure ratings for your project. Always verify the accuracy and reliability of the chart before using it for critical design decisions.

Flange Dimensions by Class and Size

Flange size charts are meticulously organized to reflect the variations in dimensions based on pressure class and nominal pipe size. This classification system ensures that flanges are properly matched for safe and reliable connections within piping systems. Here’s a breakdown of how flange dimensions are categorized⁚

- Pressure Class⁚ Flanges are rated for specific pressure classes, indicating their ability to withstand internal pressure without failure. Common pressure classes include 150, 300, 400, 600, 900, 1500, and 2500. Higher pressure classes correspond to thicker flanges with greater structural integrity.

- Nominal Pipe Size (NPS)⁚ Flanges are designed to fit specific pipe sizes, denoted by NPS (Nominal Pipe Size). The NPS corresponds to the internal diameter of the pipe, and flange dimensions are adjusted accordingly to ensure a snug fit. Common NPS ranges from 1/2 inch to 24 inches, with specialized sizes available for specific applications.

Flange size charts typically list the following dimensions for each pressure class and NPS combination⁚

- Outside Diameter (OD)⁚ The overall diameter of the flange, including the raised face.

- Bolt Circle Diameter (BCD)⁚ The diameter of the circle that defines the locations of bolt holes.

- Bolt Hole Diameter⁚ The diameter of each individual bolt hole.

- Flange Thickness⁚ The overall thickness of the flange, including the raised face height.

By referencing the chart, engineers and designers can easily determine the appropriate flange dimensions based on the required pressure class and pipe size, ensuring a secure and compatible connection for their piping system.

Flange Bolt Chart⁚ Essential Information

A flange bolt chart is a critical companion to a flange size chart, providing essential information about the bolts used to secure flanges together. This chart is crucial for ensuring proper bolt selection, installation, and overall system integrity. Here’s what you can expect to find in a typical flange bolt chart⁚

- Bolt Size⁚ The chart specifies the diameter and length of the bolts required for different flange sizes and pressure classes. This ensures that the bolts are strong enough to withstand the stresses of the application.

- Bolt Grade⁚ The chart indicates the grade of the bolts, signifying their tensile strength and resistance to stress. Higher grade bolts are typically required for higher pressure applications and critical piping systems.

- Number of Bolts⁚ The chart specifies the number of bolts needed for each flange size and pressure class. This ensures that the flange is adequately secured with the appropriate number of bolts.

- Bolt Circle Diameter (BCD)⁚ The chart provides the BCD for each flange, indicating the diameter of the circle that defines the location of the bolt holes. This ensures that the bolts are evenly spaced around the flange.

Flange bolt charts are often presented alongside flange size charts in a single PDF document, making it easy to cross-reference the information. This integrated approach simplifies the selection process and ensures that the correct bolts are chosen for a specific flange configuration.

Flange Dimensions in Metric Units

While flange size charts traditionally use imperial units (inches), many applications, particularly in Europe and other regions, require flange dimensions in metric units (millimeters). A dedicated section within a flange size chart PDF that focuses on metric dimensions is crucial for international projects and for those working with metric standards. This section will typically include the following information⁚

- Nominal Pipe Size (NPS)⁚ The chart will list the NPS (Nominal Pipe Size) in millimeters (DN ౼ Diameter Nominal), corresponding to the internal diameter of the pipe. This allows users to quickly identify the appropriate flange for their specific pipe size.

- Outside Diameter (OD)⁚ The OD of the flange, measured in millimeters, is essential for determining the overall size of the flange and for ensuring compatibility with other components in the system.

- Flange Thickness⁚ The thickness of the flange, measured in millimeters, is critical for determining the strength and pressure rating of the flange. This dimension is crucial for selecting flanges that can withstand the intended operating conditions.

- Bolt Hole Diameter⁚ The diameter of the bolt holes, measured in millimeters, is necessary for selecting the correct bolts and ensuring a secure connection.

- Bolt Circle Diameter (BCD)⁚ The BCD, measured in millimeters, determines the spacing of the bolt holes around the flange, ensuring proper alignment and even distribution of stress.

Having a clear and comprehensive section dedicated to metric flange dimensions in a PDF chart ensures seamless integration with international standards and facilitates efficient selection of the correct flanges for various projects.

Flange Dimensions for Specific Applications

While general flange size charts provide valuable information for common applications, specialized applications often require specific flange dimensions tailored to their unique requirements. A comprehensive flange size chart PDF might include sections dedicated to specific applications, offering critical dimensions and specifications for these specialized scenarios. These sections can cater to⁚

- High-Pressure Applications⁚ Flanges used in high-pressure systems require greater thickness and strength to withstand the demanding operating conditions. The chart would include dimensions for flanges designed for classes 1500 and 2500, as well as specialized materials like stainless steel or high-alloy steels.

- High-Temperature Applications⁚ Flanges in high-temperature environments require special materials that can resist creep and fatigue. The chart would include dimensions for flanges constructed from materials like Inconel or Hastelloy, along with appropriate thicknesses and reinforcement details for elevated temperatures.

- Vacuum Applications⁚ Flanges used in vacuum systems require precise sealing and low outgassing. The chart might include dimensions for specific flange types like Conflat flanges, which are commonly used in vacuum chambers and instrumentation.

- Specific Industries⁚ Certain industries, like power generation, oil and gas, or chemical processing, have unique requirements for flange dimensions. The chart could include sections dedicated to these industries, showcasing flange dimensions for specific applications within each sector.

This approach ensures that users can readily find the specific flange dimensions they need for their specific application, enhancing accuracy and efficiency in selecting appropriate components for their projects.

Flange Size Chart PDF⁚ Benefits and Uses

A flange size chart PDF offers numerous benefits and has various uses for professionals working with piping systems and related equipment. Here are some of the key advantages and applications of these charts⁚

- Accurate Selection⁚ Flange size charts provide precise dimensions and specifications for different flange types and sizes. This helps ensure accurate selection of the right flanges for specific applications, minimizing the risk of incorrect fitting or mismatched components.

- Time Efficiency⁚ These charts eliminate the need to manually calculate dimensions or refer to multiple sources. They provide readily accessible information, saving valuable time during design, procurement, and installation phases.

- Improved Communication⁚ Flange size charts provide a common language for communication between engineers, designers, manufacturers, and contractors. They ensure everyone involved is working with the same information, minimizing misunderstandings and errors.

- Enhanced Safety⁚ Accurate selection of flanges based on proper dimensions and specifications contributes to the overall safety of piping systems. By ensuring secure connections and minimizing leaks, the charts promote safe and reliable operation.

- Cost Optimization⁚ By selecting the right flanges for each application, flange size charts help avoid oversizing or undersizing components. This optimizes costs and material usage, contributing to a more efficient and cost-effective project.

Overall, flange size chart PDFs are essential tools for professionals involved in various industries where piping systems are critical. They promote accuracy, efficiency, communication, and safety, ensuring the smooth and successful execution of projects.

In conclusion, a flange size chart PDF is an indispensable resource for anyone involved in the design, construction, and maintenance of piping systems. These charts provide a comprehensive overview of flange dimensions, specifications, and other critical information, ensuring accurate selection, efficient communication, and a high level of safety in various applications. Whether you are an engineer, designer, contractor, or manufacturer, having access to a reliable flange size chart PDF can significantly enhance your workflow, minimize errors, and optimize project outcomes. By utilizing these valuable resources, you can ensure the integrity and performance of your piping systems while adhering to industry standards and best practices.